by Mark R. Johnson

Bend Living, Spring 2005

Easing into one of Robert Seliger’s custom armchairs, the body drops in just right, the proportions feel dead-on. Robert however, shakes his head and says, “That chair’s going to be made for you, just like a custom shoe.” That’s his niche, he explains, designing pieces made exactly for the individual, particularly chairs to accompany his substantial tables. “All traditional joinery,” he says of the work. “I ship these all over the world.” A production-oriented furniture maker can churn out 50 to 100 chairs a week; Robert might do four.

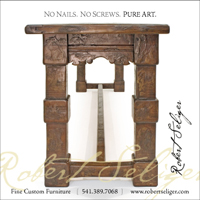

It’s hard not to run a hand over the trestle table that dominates his drafting room. The thick top, showing butterfly joinery, is surfaced in a blend of hand-rubbed stain, lacquer and sealer. “The finishing really sets it apart,” he says, pleased to have his work called an art. “Check this out,” he says, dropping a knee to the floor and knocking a palm against the tenon that holds the side and stretcher together. He pulls on the side piece gingerly, showing how it’s all held together by the precision of perfectly fitted elements.

Robert describes his work as having a European influence, a country flavor, but agrees that it’s a look that defies categorization. He strives to create graceful lines, eliminate sharp corners and create an overall refined look, as though the pieces had been worn over time. “When all of the material comes in here it’s square—very true—and I take it backwards from that,” he says. “I put the life and the character into the piece.”

A native of Aspen, Colorado, Robert dove into woodwork straight out of high school, cutting his teeth as a finish carpenter in a shop where everything that went into a custom home was built on site. That was 30 years ago. When he moved to Bend, in 1990, he built his own home while also keeping his craft going. “With two kids, living in a trailer—amazing journey,” Robert says, laughing. And the business has certainly grown: estimates that he and a single employee will put out more than 300 pieces this year. He might be lathing a 300-pound block of wood into a table base one day and carving an intricate panel fronting a colossal armoire the next. “That’s what’s so nice about this,” he says. “It’s always changing.”

“When you’re getting going in this, you’re seeing these furniture makers, the high-end ones, you’re seeing their work on a pedestal and it’s awesome, and you’re hoping one day you’ll get there,” Robert says. “Now I can put these pieces against anyone in the world.”